TES VSETIN a.s.

Jiráskova 691, 755 01 Vsetín, Czech Republic

Show on map | Privacy Policy | General terms and condtions | Whistleblowing

Complex offering in the field of test stands and automation solutions for car manufacturers and subcontractors. Company TES VSETÍN s.r.o. has the 100 years history and is the follower of traditional producer MEZSERVIS s.r.o.

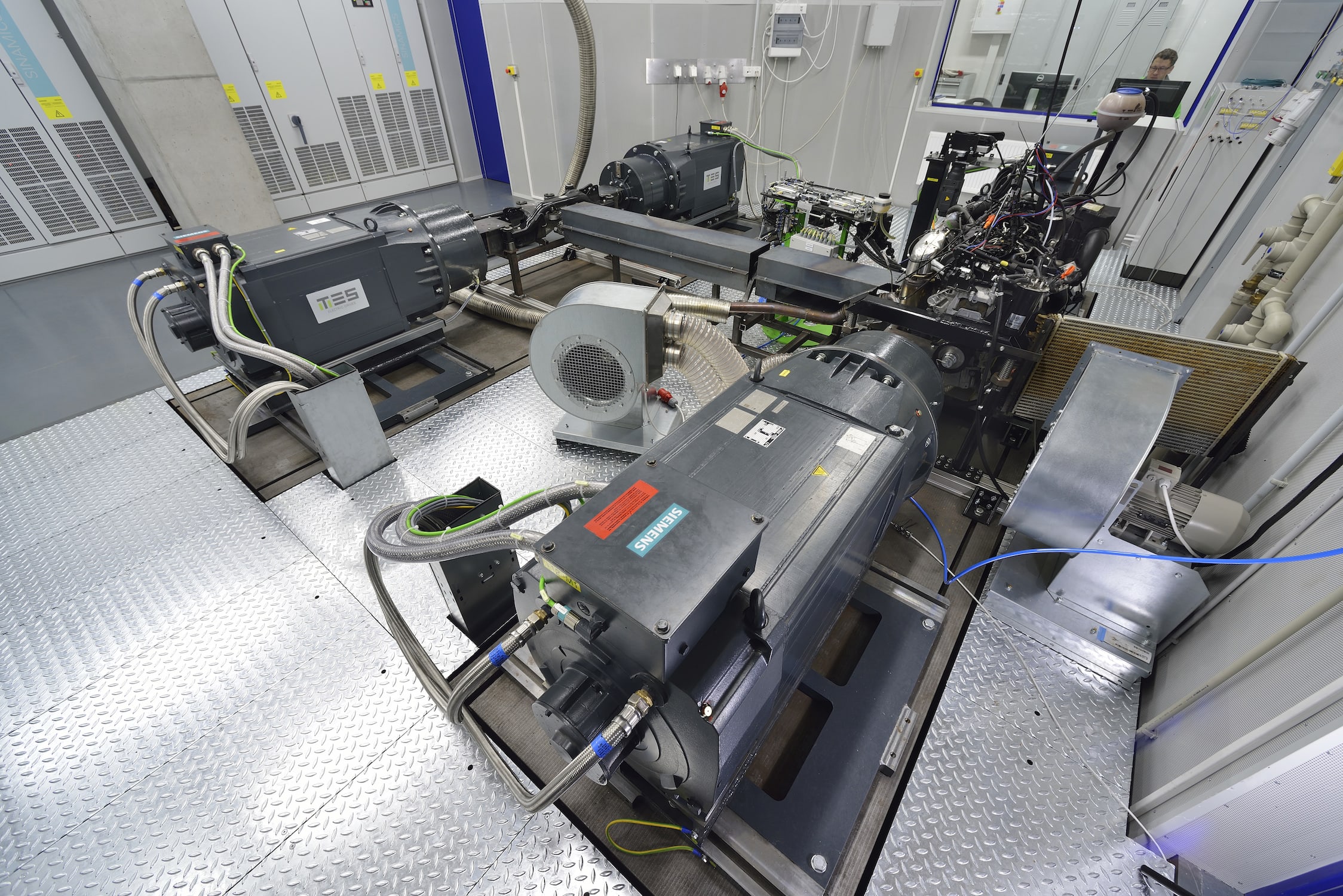

Our expertise in the production of testing equipment is rooted in our long tradition in the design and production of electric drives with dynamometers.

Our products may be used to test combustion engines, electric rotating machines, fans, pumps, compressors, gearboxes, distributor gears and whole vehicles. Our supply includes the complex technical solution of the whole test stand, including all measuring components, power components and mechanical components.

With a view to operating our test bed, we have developed its own CMS software. The CMS programme measures, depicts and records all magnitudes which are necessary for testing processes and procedures. The software is largely configurable, easily adjustable to particular motor types, and adaptable to all sorts of end-user demands.

Our modular vehicle test stand is designed for car manufacturers and large service centres, as well as for educational and R&D institutions. The test stands consist of DC dynamometers or asynchronous dynamometers used to actuate or brake the objects tested. They allow the measurement of torque, rotational speed, mechanical output and power input. Their strengths include high accuracy, easy configuration and operating mode control.

Test stands for diesel engines and spark-ignition engines are intended for long-term testing and run-in testing in the automotive industry. They can be used for the highest quality testing including audit test stands.

These test benches are used to adjust, run-in and test hydrodynamic gearboxes, distributor gears and brake lining. The stand consists of an electric dynamometer gearbox, a locking brake, a brake and a cooling oil circuit. It works on the principle of dynamometers with a control system. The control system is used to collect the values measured, to program and configure the test, to monitor the limit values, to control the course of the test, and to automatically archive all data and print out a report.

| Max. test speed: | 200 km/h |

| Max. load per axle: | 2,000 kg |

| Roller diameter: | 1,200 mm |

| Roller width: | 600 mm |

| Distance between rollers: | 900 mm |

| Inertial mass of rollers on axle: | 1,130 kg |

| Max. test speed: | 16 km/h |

| Roller diameter: | 0.512 m |

| Roller width: | 1,400 mm |

| Roller wheelbase: | min. 700 |

| Distance between rollers: | 700 mm |

| Max. traction/braking force: | 160 kN |

| Max. axle load: | 15,000 kg |

| Driving torque: | do 250 Nm |

| Input rpm: | 0 – 5,000 rpm |

| Load torque on each half axle: | do 1,820 Nm |