We specialize in designing and manufacturing high-performance generators and motors with all processes handled in-house. Our expert team manages everything from initial design to final servicing, ensuring top quality and reliability at every stage.

Generators & Motors

Custom-Designed InnovationDesign and Development Competence

Discover our Products

Explore

our extensive capabilities to see how our custom-designed, state-of-the-art electric rotating machines can optimize your operations.

From Concept to Implementation – We Handle It All

Design

- Handling challenging projects.

- Customized design – adaptation of instalation dimensions, moment of inertia and other parameters.

- Precision in electromagnetic calculations using advanced tools like rmExpert, Maxwell, MotorCAD and Finite Element Analysis (FEA).

- Optimized critical components for reliability prior to production by integrating software like Autodesk Inventor and Ansys Mechanical.

- Compliance with Industry Standards.

Adaptation

of instalation dimensions, moment of inertia and other parameters.

Technology

- Focusing on efficiency, quality, and precise planning.

- We determine the optimal tools, materials, equipment, workforce, and time schedule.

- By utilizing modern CAM software, we achieve high precision in computer-controlled component machining.

Optimization

of tools, materials, equipment, workforce, and time scheduling.

Computer-Aided Manufacturing

Higher precision, efficiency, flexibility and consistency.

Procurement

- Comprehensive supply chain management with a focus on efficient communication and collaboration.

- Innovation and modernization aimed at improving productivity, quality, and sustainability.

- Quality as the top priority through precise process control and careful partner selection.

- Efficient processes supported by automation, digitization and workflow optimization.

- Openness to new partners to build long-term relationships and innovative solutions.

Speed and Flexibility

in adapting to changing market and customer demands.

Proactive Cost Management

Optimization focused on minimizing waste and maximizing value.

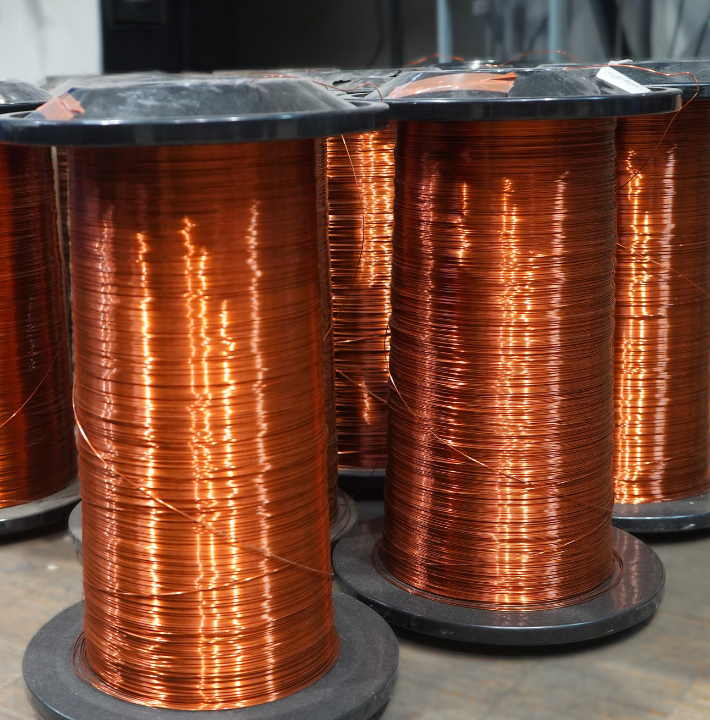

Production

- Capable of handling complex geometries and tight tolerances to ensure optimal performance.

- Utilization of in-house production capabilities – Stamping, Stacking, Welding, Machining, Winding, Impregnation, Assembly and Testing.

- Advanced testing equipment for verifying the integrity and performance of each generator or motor.

- Compliance with international standards and certifications to ensure product reliability and safety.

- Implementation of rigorous quality control throughout the production process.

All Under One Roof

Fermat WFT 13R horizontal boring mill, CNC machining centers, MTE 2500, CNC stamping line Weingarten HS 250, HUQ 250 Weingarten cutting line, ŽĎAS LKDE 400 cutting line and Schuler A2-200 progressive automatic press and many other machines.

Precision and Efficiency

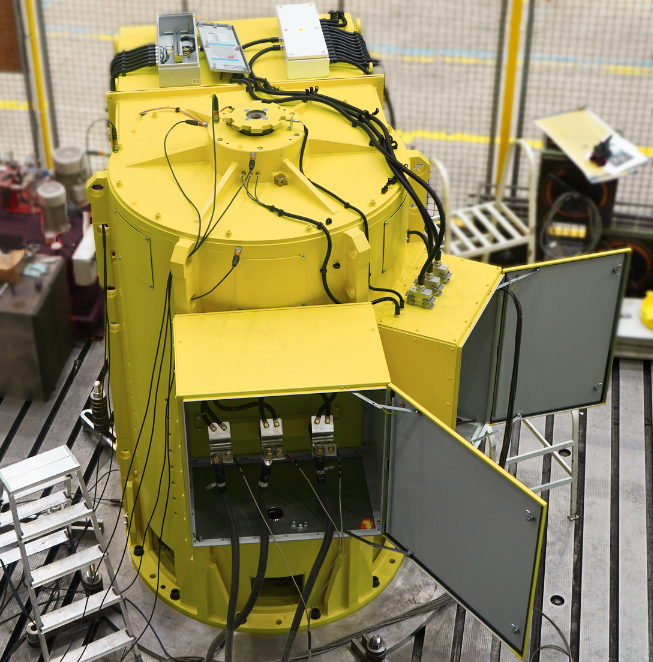

Testing

- Comprehensive testing of generators and motors focused on reliability and performance.

- High-voltage testing covers equipment with voltages of 6.6 kV and 10.8 kV and weights up to 85 tons.

- Low-voltage testing focuses on machines weighing up to 10 tons, ensuring precise diagnostics and optimal performance.

- Our testing facilities are equipped with state-of-the-art technology for detailed analysis and customized protocols.

- We offer professional solutions to ensure reliability and efficiency of your machines.

Comprehensive Diagnostics

Detailed analysis to meet industry standards and customer needs.

Commisioning and Instalation

- Each of our products undergoes a rigorous final inspection process before leaving our facility.

- Our customers are invited to our facility during the handover process during which spare parts, machine completeness, labels, packaging, and transport equipment are thoroughly inspected.

- Professional on-site installation, ensuring a seamless transition from delivery to operation can also be provided if requred by the custmer.

Rigorous Final Inspection

of spare parts, machine completeness, labels, packaging, and transport equipment.

Professional On-site Installation

Ensuring a seamless transition from delivery to operation.

Service

- Providing comprehensive on-site services to ensure optimal operation and maintenance.

- In-house repairs are conducted with precision, ensuring quick and effective solutions to any issues that may arise.

- Our overhaul services restore equipment to reliable operation, extending its lifetime and functionality.

- Wide range of spare parts sourced quickly to minimize downtime.

On-site Services

Optimal operation and maintenance of our machines is ensured.

Downtime Minimized

Spare parts sourced quickly to minimize downtime.